Ointment Manufacturing Plant

As a leading plant in the pharmaceutical industry, we specialize in producing top-tier ointments that cater to diverse medical needs. Our state-of-the-art facility, coupled with stringent quality control measures, ensures the creation of effective, safe, and reliable products. With a commitment to excellence and cutting-edge technology, we are dedicated to delivering premium ointments that prioritize customer well-being and satisfaction. Explore our range of meticulously crafted formulations designed to make a difference in healthcare.

Ointment Manufacturing Plant

- cGMP production plants.

- Minimum human involvement needed.

- Option of PLC, HMI based model.

- 21 CFR Part 11 compliant SCADA package available on demand. (optionally)

- Almost zero vacuum drop during the mixing and blending process.

- Uniquely designed to address all crucial factors directly or indirectly affecting the production quality.

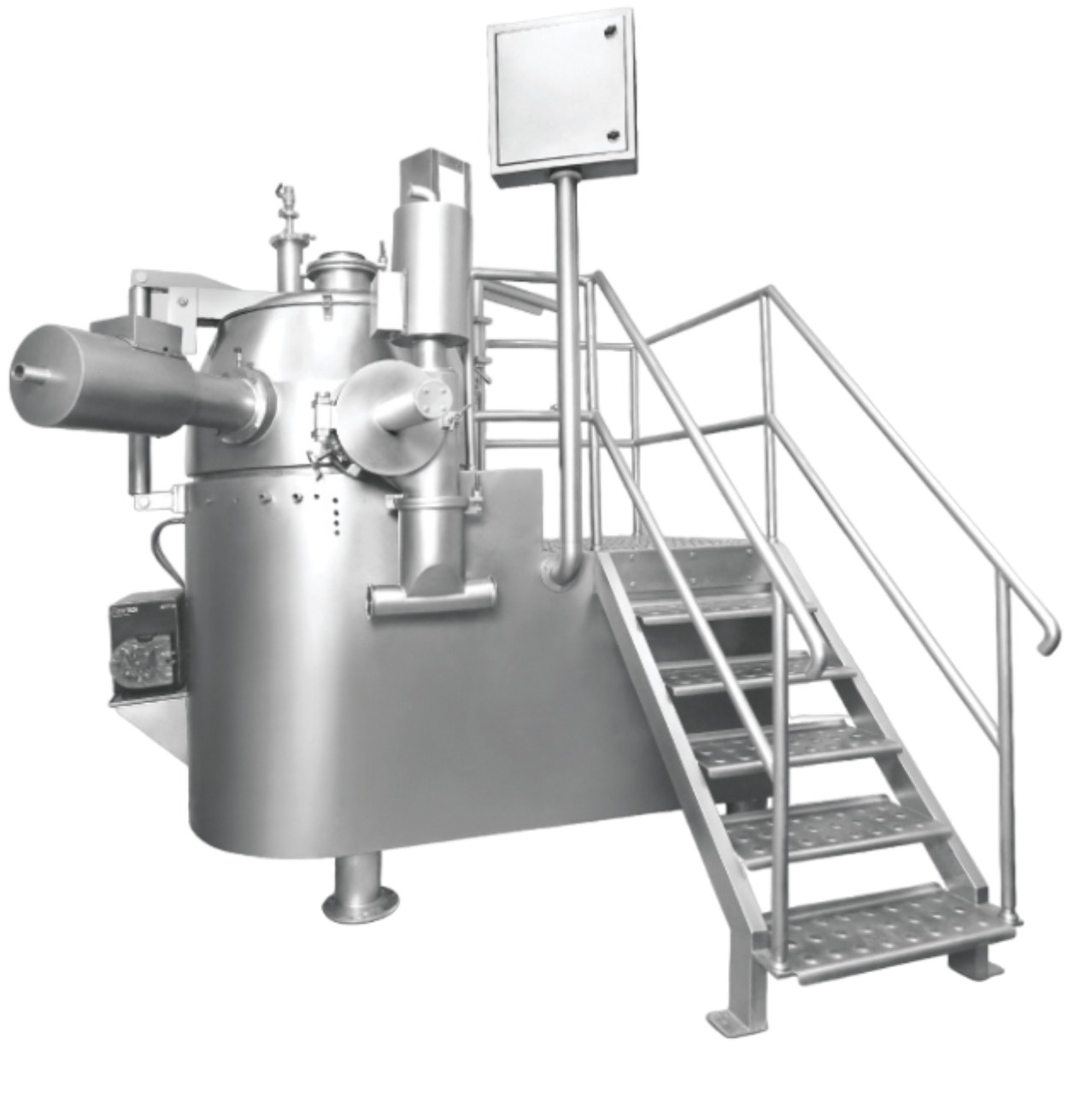

- Ideal for the production of variegated ointments, lotions, gels, emulsions, toothpastes, and homogenizations.

- All contact parts made of SS316 and teflon material.

- Hydraulic lid lifting and tilting arrangement of the main vessel to facilitate cleaning at the time of product change over.

- Specially designed stirrer with flexible teflon scraper.

- Mixing principles are matching with international standards.

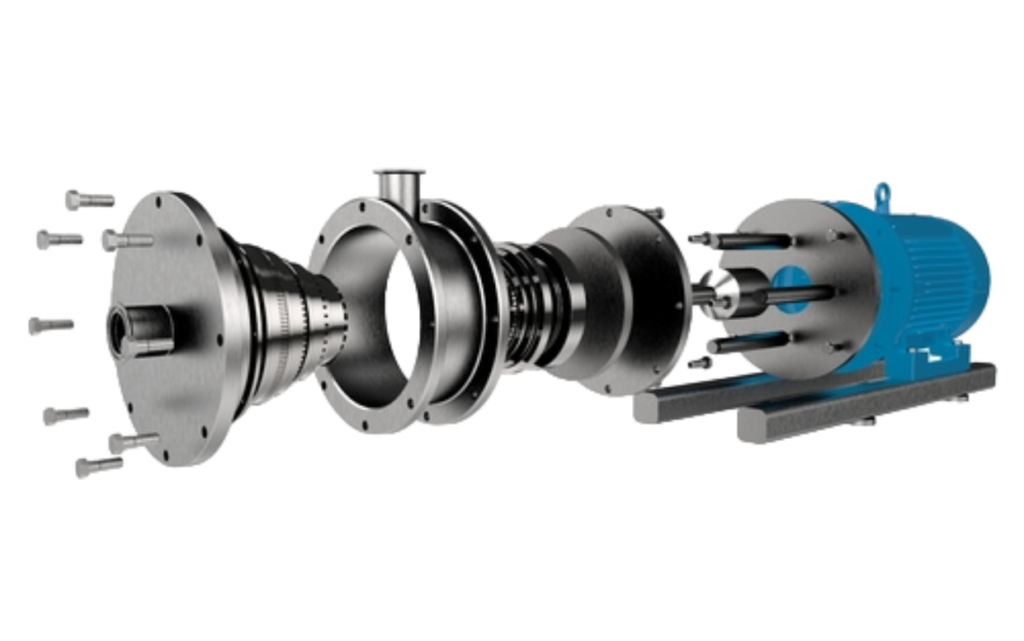

- Variable speed provided for stirrer and homogenizer for different speeds.

- All transfer done through vacuum to avoid any hand touch and contamination.

- Homogenizer fitted in the main shaft to ensure high shear emulsification and homogenization of the product.

- Specially designed inline filter to ensure proper filtration.

- Minimum change over time.

- Pneumatic / hydraulic lifting to lid manufacturing vessel.

- Mixing vessel consists of two speed agitators and one variable fast speed agitator.

- All vessels are cGMP.

- The plant is designed to be operated by only one operator and one helper.

- Gaskets used are made of silicon materials.

- The entire plant is equipped with CIP & SIP connections, so that customer can use this facility, if have CIP & SIP equipment.

- All values of the temperature and time of the plant are indicated digitally on the control panel.